Industry 4.0 with Smart Injection Plant

- PROSCO

- Dec 6, 2019

- 3 min read

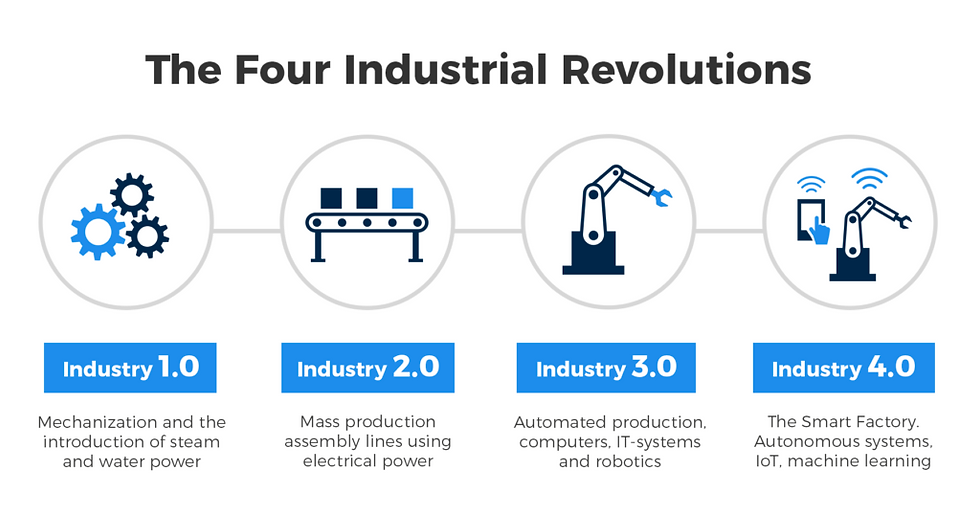

After industry 4.0 was proposed, the man start to realize that they need technical to change their life and led to constant technological change.

The industrial revolution was a major change in the course of human development, everyone need the goods for use. But with the development of the years, the customer give a high requirement to the manufacturer, not only include the price, but also the quality.

90% of goods are related to plastic. Indeed, plastic is an importance materials in our life. When we pack the wet food, we need plastic bag or plastic boxes and etc. When we drink the milktea at shopping mall, maybe we use the plastic cup and plastic straw; When we wash the clothing, we use plastic bucket or plastic basin. Pen, laptop, shoe, key, watch, children toys, mouse, plastic bottle, cellphone case and etc., as you see, plastic product is around our life.

However, how does the manufacturer can stand out from the competition? Not only you need the excellent injection machine, but also need a smart conveying integrated system, plastic granule feeding system.

Firstly, we need to understand why we need this system?

Here is the reasons to tell you choose conveying system,

- You have dryers on 10 or more machines

- You have a single material that requires drying and it is required at multiple machines

- You have frequent material changes on your machines

- You use more materials types than you have machines

- You have dryer to dryer quality issues when drying the same material

- You want to expand, but do not have sufficient space

Do you know a central drying / conveying system helps manufacturers overcome various matters and saving hundreds of thousands of dollars per year?

1. Over-drying Protection

Efficient eliminates over-drying of moisture sensitive resins, like nylons.

2. Faster Changeover Times

Increases machine uptime and production.

3. Minimizes Labor and Floor Space

Removes press-side dryers, hoppers and forklifts from the production floor.

4. Easy Access Maintenance

All maintenance can be performed from the front of the dryer.

5. Intelligent Regeneration

Constantly monitors regen inlet and outlet temperatures and controls them to optimize energy and dew point performance.

6. Variable Frequency Drive

Dryers from - 1600 through - 5000 employ a variable frequency drive that automatically optimizes the regen blower speed.

7. Proven Fast Payback of Investment

A plant survey can compare your current costs to estimated costs with a Central System and prove the payback you can expect.

8. Clear Text Messages

No confusing codes that have to be looked up.

9. Standards that Others Call Options!

- Data trending of processes

- 7 days Timer with Auto START/STOP

- After-cooler water/ plasticized drain

- Dew point analyzer

- High heat capability

- Phase detection on all portable dryers

- Reliable chain drive

- Filter maintenance alarm

- Alarm Light

- Disconnect switch

Press Side VS Central Drying

Press side

● Approximately 75 sq. ft. per station is wasted with dryer, hopper and gaylord.

● The energy lost with dryer and loader at every station.

● Process variations occur with different dryers reducing quality.

● Extra labor and equipment to keep machines supplied with material.

● Every material changeover can cost 2 or more hours of lost production.

● The inevitable loss of material when changing materials.

Central Drying

● Optimum drying of multiple materials using a central source for dry air.

● Process stability with central dryer and proper airflow/temperature at each hopper.

● Increase floor space for more machines and greater production.

● Reduced labor and maintenance.

● Fast material changeover greatly increases process machine uptime.

● Material selection with automatic identification reduces material waste and rejects it.

How does central drying work?

● The central dryer is your single source for -40º dew point air.

● A heater/blower at each hopper provides proper air flow and drying temperature.

● Dry air conveying or dry air purging of lines is available.

● Integrated central conveying system with auto ID of materials minimizes waste.

● Change materials in minutes... not hours for increased production time.

● Multiple Materials - Central Drying with Closed Loop Dry Air Convey

● Over-dry Protection.

Monitors hopper outlet temperature and adjusts hopper inlet temperature when hopper is not utilized at full throughput capacity to avoid over-drying of resin.

Inquiry PROSCO right now!

E-mail: cnprosco@gmail.com

Comments